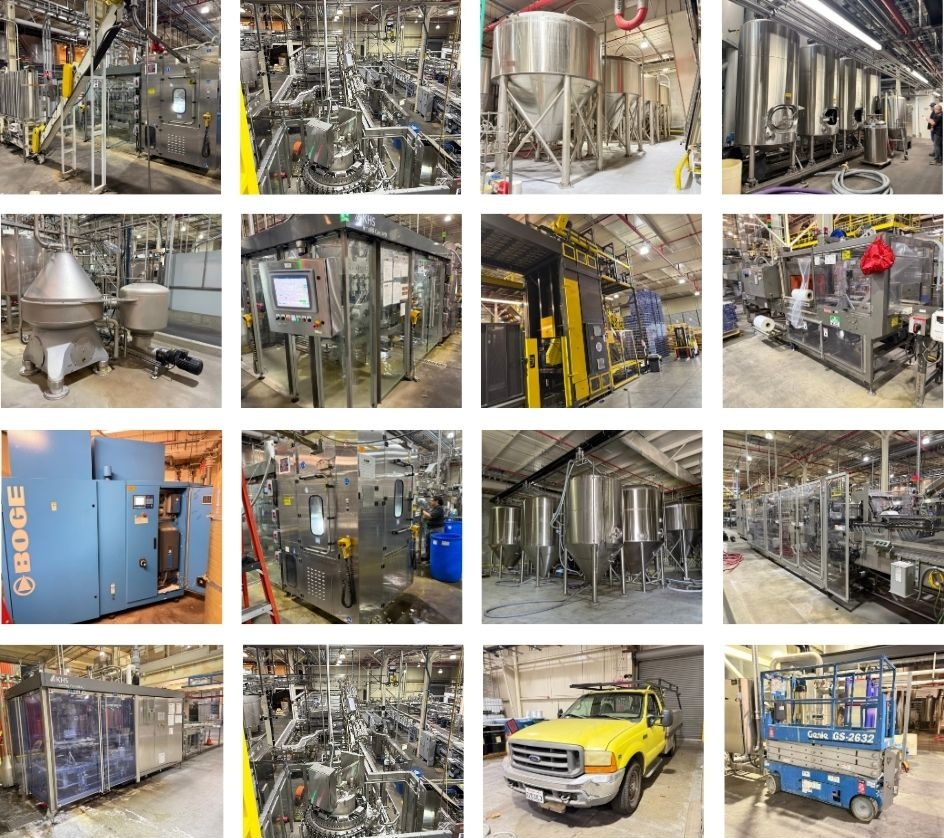

Operating / In-Place Offering*

Co-Packing Facility w/ 300,000 Barrel Brewery

Over $44 Million CapEx Invested – 108,000 sf Facility

21st Amendment Brewery – San Leandro, CA

Upcoming

FORMERLY OPERATED BY 21st AMENDMENT BREWERY – LOCATED IN SAN LEANDRO (BAY AREA), CA

The 21st Amendment co-packing production facility in San Leandro offers a rare, turnkey brewery opportunity in one of the Bay Area’s leading brewing corridors. The facility is currently operational and includes an installed KHS 530 CPM canning line—enabling immediate brewing, packaging, and onsite service—plus a large-scale brewhouse, extensive tank infrastructure and built-out taproom.

Located within a purpose-built industrial facility, the property provides scale and flexibility for an owner-operator, expanding brewery, or contract brewing platform seeking a production-ready presence in San Francisco Bay Area.

*Operating / In-Place Sale – Subject to New Lease Consummation with Landlord

FACILITY HIGHLIGHTS:

- 108,000± sq ft facility with operating high-speed 530 cpm KHS volumetric canning line

- Can Production Compatibility – 8, 12, 16 and 19.2 oz cans – 211 (standard) or 202 (sleek)

- Highly automated Douglas Spectrum multi-packer cartoner, capable of packing multiple sizes (4 to 30 can pack) with a variety-pack spur

- Multiple zone tunnel pasteurizer

- Quality control/assurance lab with the ability to provide all necessary product line checks from production to package including micro-plating

- 155,000 US barrels current cellar capacity, expandable as needed

- GEA Westfalia centrifuge solids separator with sterile pad filtration availability

- 100 barrel five-vessel German engineered GEA brewhouse with 10-12 turns/24 hours capable of brewing 300,000 beer barrels annually

- Broad tank size configuration: 100, 150, 200, 500 barrel tanks

- Distilled spirits permit for RTDs and FMBs

- Flash pasteurizer capability

- Variety Packing capabilities with multiple sizes and configurations including loose pack

FEATURED EQUIPMENT:

- KHS 530 CPM State-Of-The-Art Canning Line

- GEA 5-Vessel 100 Barrel Brewhouse

- Fermentation Tanks To 500-Barrel

- Brite Tanks To 400 BBL

- KHS Keg Wash/Clean/Fill System

- GEA Westfalia GSI-200-06-772 Centrifuge

- Kunzel Grain Mixing System with Kunzel Grain Mill

CANNING LINE – 6,000,000 ANNUAL CASES / KHS 530

- KHS Innofill Can DVD 40 Valve Volumetric Can Filler

- Angelus 6V Can Seamer

- G.C. Evans Stainless Pasteurizer

- Douglas Spectrum Cartoner & Multi Packer

- Kayat TP-50 Continuous Motion Tray Packer

- Sentry Bulk Depalletizer & Case Palletizer

- ARPAC Overwrap System w/ Shrink Tunnel

- Lantech Q300 Pallet Wrapper

- Can Production Compatibility: 8, 12, 16 and 19.2oz cans

- 211 (standard) or 202 (sleek)

BREWHOUSE & STAINLESS CAPACITY

- GEA 5-Vessel Automated 100 Barrel Brewhouse

- (10) Zieman 500 BBL fermenting tanks (15,750 gal)

- (8) Marks 200 BBL fermentation tanks

- (10) Marks 150 BBL fermenting tanks (2022)

- (6) Zieman & Marks Brite tanks up to 580 BBL

- (2) Mueller 300 BBL brew water tanks

- GEA Westfalia GSI 200-06-772 self-cleaning disc stack centrifuge (2014)

- Centec DGS Water Deaeration System

- 5 Tank 47 BBL Yeast System

- Kunzel Grain Mixing System with Kunzel Grain Mill

- Wide Assortment of Pumps, Plate Heat Exchangers & Buffer Tanks

PLANT SUPPORT EQUIPMENT

- KHS Innokeg Combikeg Rotary Keg Filler and Cleaner

- (3) GEA CIP Systems for Brewing, Filling & Tank Washing

- SEN Orion OF100, 39″ X 39″ Plate & Frame Filter

- A&B Process Pasteurizing System

- Grain Storage System With (3) Meridian 200 & 250-Barrel Silos

- York And Carrier Chiller Systems

- BOGE 100 Hp Air Compressor, Quincy Air Dryer

Sale in conjunction with

Images