CalPlant - Complete Facility Closure - By Order of the US Bankruptcy Court - Case Number - 1:21-bk-11302 | CalPlant I Holdco, LLC

Orderly Liquidation / Negotiated Sale - Late Model MDF (Medium Density Fiberboard) Manufacturing Facility - Facility Launched in 2020 - Over $380 Million Invested

Ongoing

Best and Final Bids Due

June 28, 2024

LOCATION

Willows, CA

MEMORANDUM / NOTICES

Sale Brochure

CalPlant – MDF (Medium Density Fiberboard) Manufacturing Facility – Orderly / Bulk Sale Offering EXTENDED – Best and Final Offers Due by April 5, 2024!

Complete Willows, CA Facility Closure – Launched in 2020 – Over $380 million Invested

By Order of the US Bankruptcy Court – Case Number – 1:21-bk-11302 | CalPlant I Holdco, LLC

CalPlant I Holdco LLC and its affiliates and subsidiaries (“CalPlant”), a Northern California-based company focused on manufacturing sustainably-sourced building products, including the world’s first no-added-formaldehyde, rice straw-based medium density fiberboard Eureka™ MDF, has been approved by the United States Bankruptcy to proceed with an orderly liquidation sale of the complete CalPlant production facility.

Plant Summary (In Order of Production Flow)

(4) Straw Bale Receiving, Chopping & Pulverizing Lines

Design process of 9 to 12 tons of straw bale per hr., each consisting of:

- Nybladt 158 kW drum choppers with bale destringing & pre cutters

- Pallmann 200/400 kW hammermill pulverizing systems

- Explosion proof pnuematic transport systems with 152 kw blower/fans

- Baled straw receiving conveyors supported by (2) shuttle carriages

- (1) 16,000 kG overhead bridge crane with bale grapple & remote control

- Pit type troughing belt chain removal conveyor for stones & waste

(4) Primary Cleaning & Separating Systems

Design process of 9 to 12 tons of material @ 45 kg/m3 bd, consisting of:

- Ventapp silicate separator stations with pre separating chambers

- Twin screw integrated blending conveyors with straw distributer/sifters

- Ventapp extraction/filter cleaning systems with large hp power fans

- LHS bag filter/ dust collection systems with explosion proof flaps

- Straw dosing & metering bin measuring 32 m x 4 m wide x 6 m deep

- Troughing belt transfer conveyors of 17 & 37 meters (to refiner plant)

Pallmann Refining Plant

2) Refiner systems with total design capacity of 28 tons/hr bd, consisting of:

- Pallmann PRS-258/64 high voltage refiners with 3500 kW 4160-volt motors

- Pallmann PR24 pin drum feeder with 500 kW main power & 22.5 kW feeder

- Horizontal digester, 2000 mm dia x 10000 mm long, 75 hp gear drives

- Stainless double screw refiner feed conveyor, 37 meter, 37 kW gear drives

- Armstrong hot water heater with conditioning & dilution water pumps

- Remote controlled blow back pipe transfer system to fiber drying area

Fiber Drying & Wet Electronic Precipitator Systems

Fiber drying design capacity of 28 tons/hr., summarized as follows:

- Intake temp of 220 deg. C, with 270,000 m3h exhaust volume

- 20 mW gas burner with 770 kW 4180v high voltage main power fan

- Double mixing chamber type with high efficiency cyclone separator

Wet electrostatic clean air precipitator system, consisting of:

- 200 kW design power, 540 KW HT high voltage system, 95% blue haze eff

- Electrostatic filter designed @ 95% blue haze efficiency, 10-30% VOC.

- Exhaust gas stack with internal scrubber components & quench duct

- Stainless sedimentation & buffer tanks, plus water screening & pumps

MDF Sifting & Material Transport System

nclosed fiber sifting system designed for 28 ton/pr MTF fiber with

- Side by side fiber sifting towers utilizing multiple radial fans to 250 kW

- Twin screw 15 kW distribution conveyor feeding sifting towers

- Multiple LHS type WN 1500 rotary air locks with 11 kW gear drives

- Heavy duty inclined troughing belt conveyors up to 80 meters length

- High pressure pneumatic material handling systems with 45kW blower

- Assortment of Ventapp round & rectangular collection hoppers

- ATEX protective T injector system plus explosion proof diverter flaps

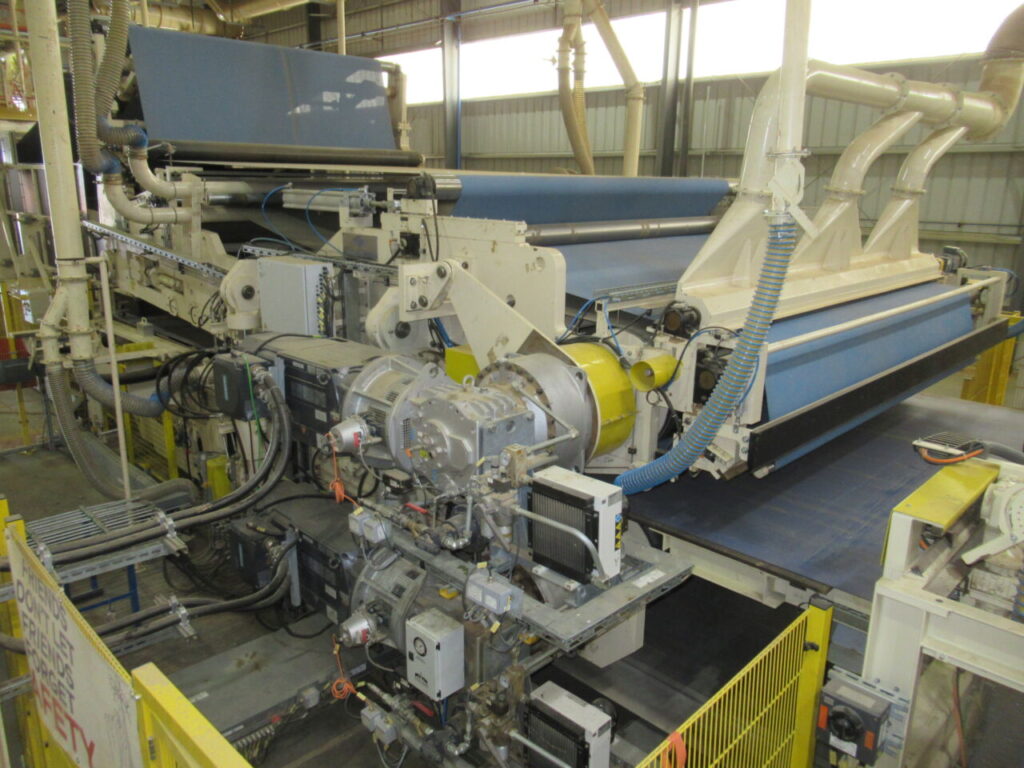

Fiber Mat Forming Segment (partial listing)

Designed for continuous spreading of MDF fiber consisting of

- Overhead blender, fiber bunker, metering retarder & distribution unit

- Continuous pre-press section for compacting fiber mat into 3500 mm width

- Automated Inline belt scale/reject segment, and infrared moisture metering unit

- Ecoscan Sico Scan detection station plus thru belt type metal detection system

- Mat trimming saw segment designed for mat range of 2490 to 3380 mm width

- Mat reject hopper, + multiple moisture spraying stations & belt splicing device

- Mat forming dust extraction & collection system for trimmed fiber material

ContiRoll MDF Press & Cooling Line

Design speed of 50 mm/s to 1000 mm/s max – partial listing includes:

- ContiRoll Generation 9 MDF press of approx. 35.4 meters long (117’)

- Online X-ray density profilometer device with secondary metal detection

- Diagonal cross cutting saw segment + continuous edge trimming station

- Board weigh scale conveying with reject station with 200 kW breaker unit

- Double rotating rotary board cooling carrousel with auto feed & discharge

- Press area extraction system powered with 230 kW 4150-volt radial fan

- Thermal oil heating system featuring (3) HESS 8000 kW hot oil heater sets

Board Sanding System

Automatic coarse grain & finish sanding platform includes:

- Steinemann type 4K-4N dual unit system with combined power of 1150 kW

- Elevated structural sanding deck with sanding data system & control station

- Hydraulic board lifting & board infeed loading table with board suction carriage

- Automatic roller infeed, thru-put and board discharge conveyors

- Fully automatic two-sided optical board inspection system with 2D-3D light source

- Ventapp/LHS high-capacity dust extraction system with 362 kW 4160-volt radial fan

CTS MDF Cut-to-Sheet System with Stacking & Strapping Stations

Fully automatic board cutting & pack-off matrix – partial listing includes:

- Infeed length-rip saw station with staging table and fix table transfer segment

- Cut to length hydraulic guillotine cutter with associated waste collection station

- Otto Mayer cross cutting system with auto alignment and pusher transfer table

- Hydraulic lifting/angle/book forming table with stack roller discharge conveyors

- (2) OMS stacked board banding systems with multi-directional diversion table

- Waste material collection with Vibroplan feeders, hydraulic chippers, & load out

Production Support Installations

- Compressed air system featuring (3) Roger RMC-KRV-150-125 air compressors

- Marlo RO purified H2O skids & dissolved air flotation water treatment system

- Wide assortment of dust extraction systems with collection silos & hoppers

- Glue storage, preparation, transfer, metering & injection system (entire building)

- Large Quantity of Siemens PLC-MCC control banks & transformer substations

- Quality Assurance lab, mobile vehicle fleet, portable truck scales, shop equipment

- Huge spare parts & copper wire inventory, new/uninstalled structural systems

NOTE: CalPlant I Holdco LLC and its affiliates and subsidiaries (“CalPlant”), a Northern

California-based company focused on manufacturing sustainably-sourced building

products, including the world’s first no-added-formaldehyde, rice straw-based medium

density fiberboard Eureka™ MDF, has been approved by the United States Bankruptcy

to proceed with an orderly liquidation sale of the complete CalPlant production facility.

Video 1

[youtube]https://www.youtube.com/watch?v=khL69fPq5Wo

[/youtube]Sale in Conjunction With

Images